Products

BATTERY TECHNOLOGY

Battery Technology

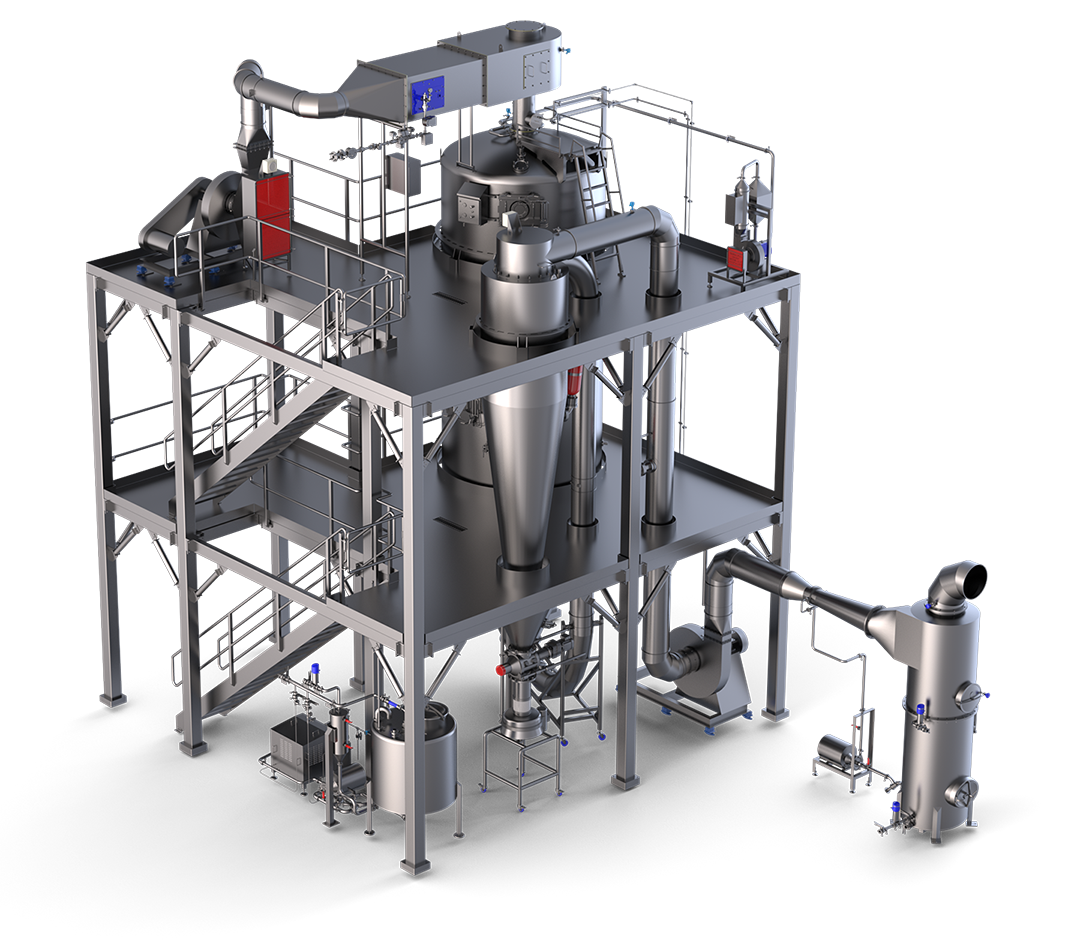

European SprayDry Technologies (ESDT) are the UK’s premier suppliers of spray drying systems with an extensive range of plant and equipment for battery technology powder production.

Battery Technology Powder Spray Drying Solutions from ESDT.

European SprayDry Technologies (ESDT) are the UK’s premier suppliers of spray drying systems with an extensive range of plant and equipment for battery technology powder production.

We are committed to the design and supply of high performance, safe and simple to operate systems and equipment which is subject to continuous review and development. Our experienced project delivery team provide a professional service to our customers which includes sales, design, project management, installation supervision, operator training and commissioning etc.

By listening and communicating closely with our clients we can deliver bespoke solutions to suit their exact requirements with a focus on performance, quality and value for money. With a global clientele, our plant and machinery is deigned to be fully compliant with both regional and industry specific standards in order to satisfy the demanding production requirements of the rapidly developing battery materials technology industry.

Three Fluid Type Atomisation Nozzles

Three fluid type atomisation nozzles are typically used on ESDT laboratory scale spray drying solutions and incorporate a nozzle cleaning needle.

High Pressure Atomisation Nozzles

High pressure atomisation nozzles are typically used on ESDT production scale spray drying solutions to effectively atomise the feed slurry prior to the drying process.

European SprayDry Technologies ‘Delivering Today’s

material development for tomorrow’s products’

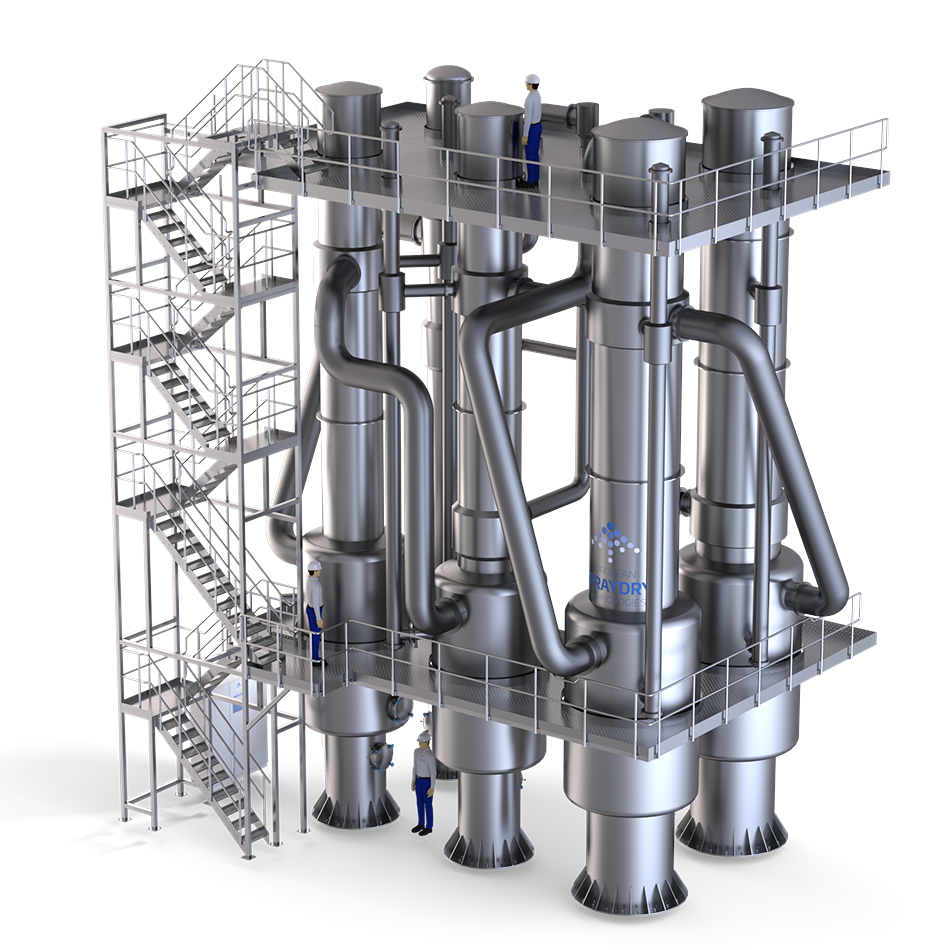

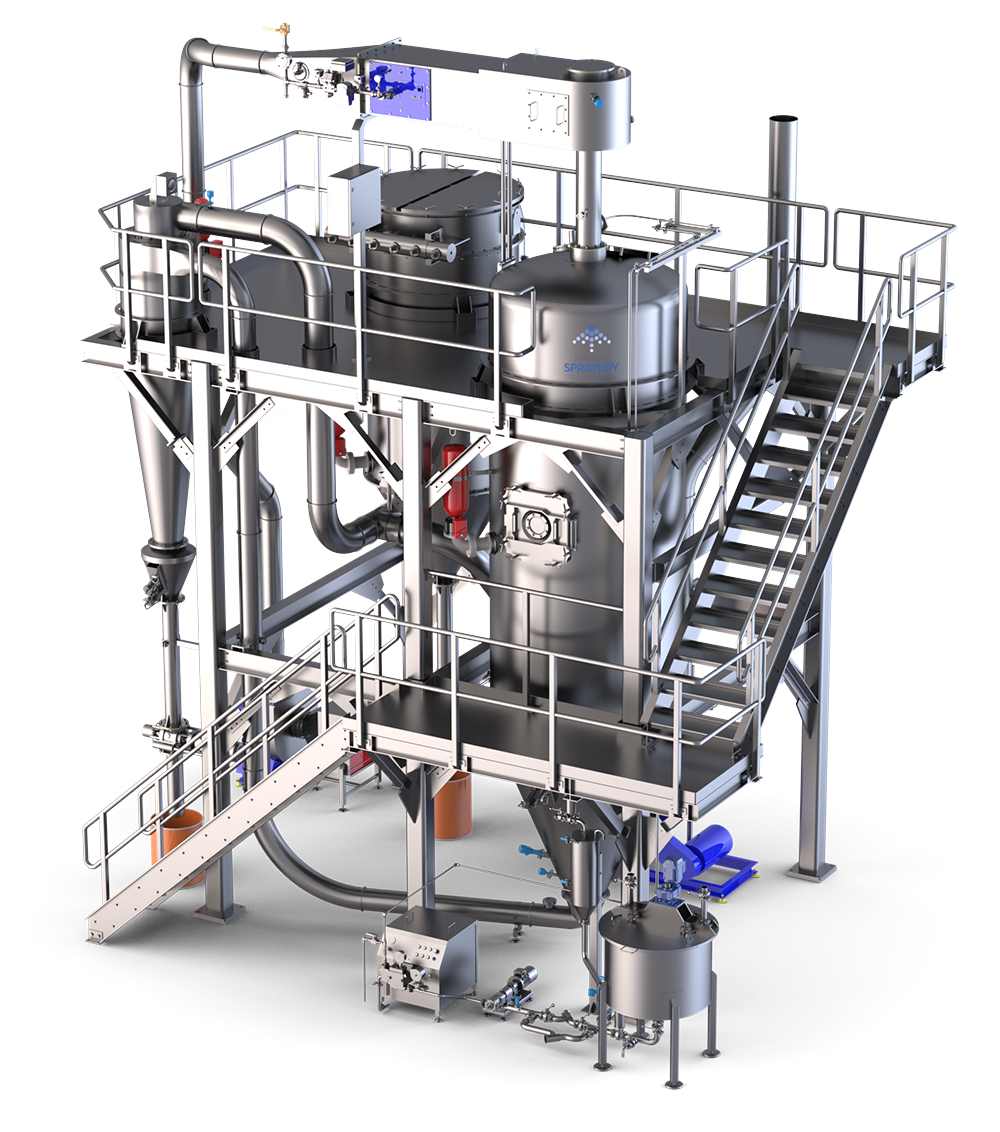

The ESDT spray dryer portfolio is based around our tried and tested ‘tall form’ spray dryer design with high pressure spray nozzle or rotary disc

atomization technology..

Spray Dryers

Learn more about the full range of spray dryers available from European SprayDry Technologies.

Including spray dryer designs specific to the recycling powder processing industry.

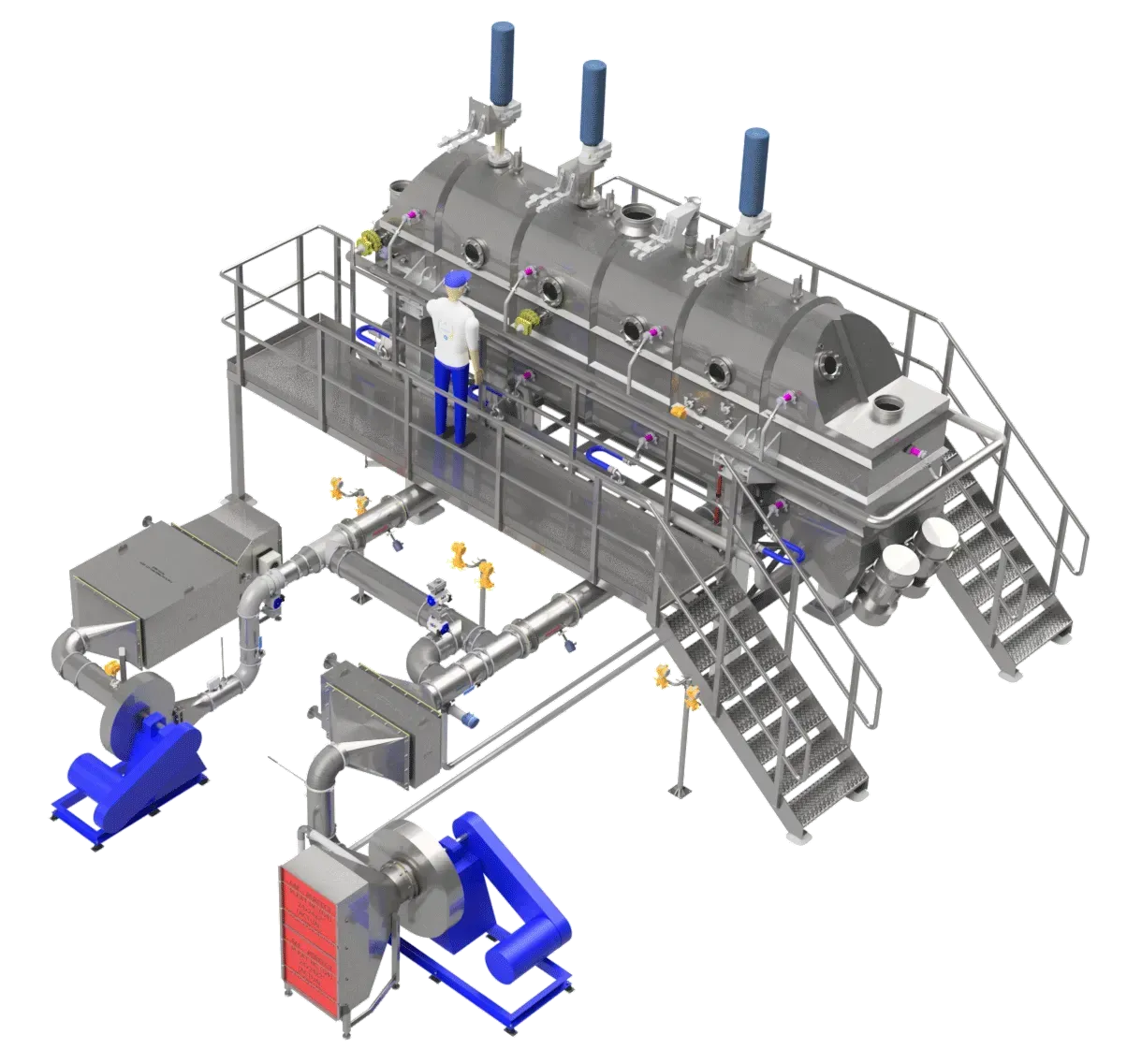

Fluid Bed Dryers

Learn more about the full range of fluid bed dryers and coolers available from European SprayDry Technologies.

Including fluid bed designs specific to the recycling powder processing industry.